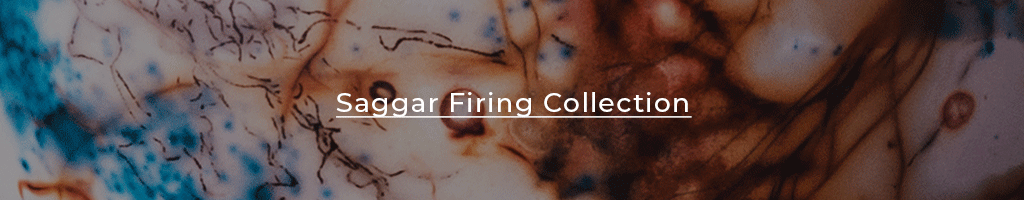

The practice of making pots using raw materials and then burnishing them without glaze, stretches back to thousand’s of years ago. Saggar also has its own unique history. Saggar is a container used during the firing process to enclose or protect ware being fired inside a kiln. Traditionally, saggars were made primarily from fireclay. Saguaros have been used to protect, or safeguard ware from open fire, smoke, gases and kiln debris. The name is a contraction of the word safeguard. The use of saggars is widespread, including China, Korea, Japan and the United Kingdom. Saggars are still used in the production of ceramics to protect ware from the direct contact of flames and from damage by kiln debris.

In this specific case, layers of aluminium and pieces of thin clay create the container. The Saggar firing is more successful if the Saggars are similar to the size and shape of the items that have to be cooked. For best results you should have a maximum of an inch of air space between the saggar wall and the creation. Saggar firing provides the most dynamic surface therefore it is not easy to polish the pieces without scratching them. Raku kiln is perfect for this type of technique and in terms of clay, it is better to use hard clay that has high thermal shock resistant.

Before firing it is important to cover the surface with Terra Sigillata (It will be also useful to catch the smoke more easily). Then, the piece is bisqued (please note not all the clays have the same bisque temperature). High temperatures can damage the piece compromising the process. After a good bisque it’s time to decorate. In this technique we use leafs, coffee, sawdust, sugar, and copper wires. Then, it needs the second firing process in the Raku kiln. Saggar Firing is a unique technique, as it is impossible to obtain the same result twice.